School Projects

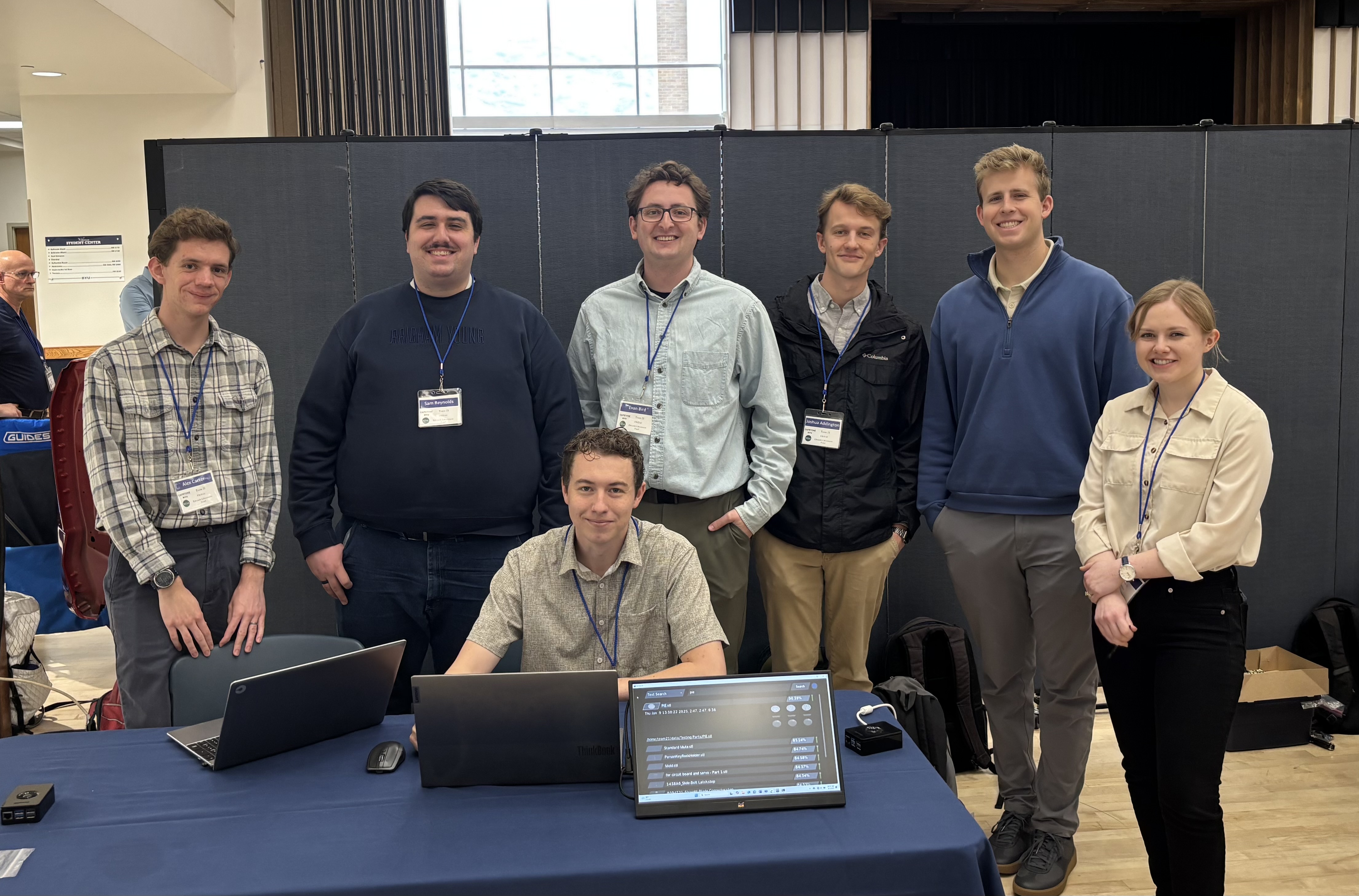

Capstone: AI-powered parts database search

During my senior year capstone project, I was part of a team that developed an AI-powered search tool for 3D CAD models. The goal was to improve the efficiency of finding specific parts for engineers working at a major biomedical device company. At a high level, the tool used a rendering engine to generate images of 3D CAD models, evaluated them using a CLIP model, and then compared user queries to the parts database using a cosine similarity score to return the most relevant results.

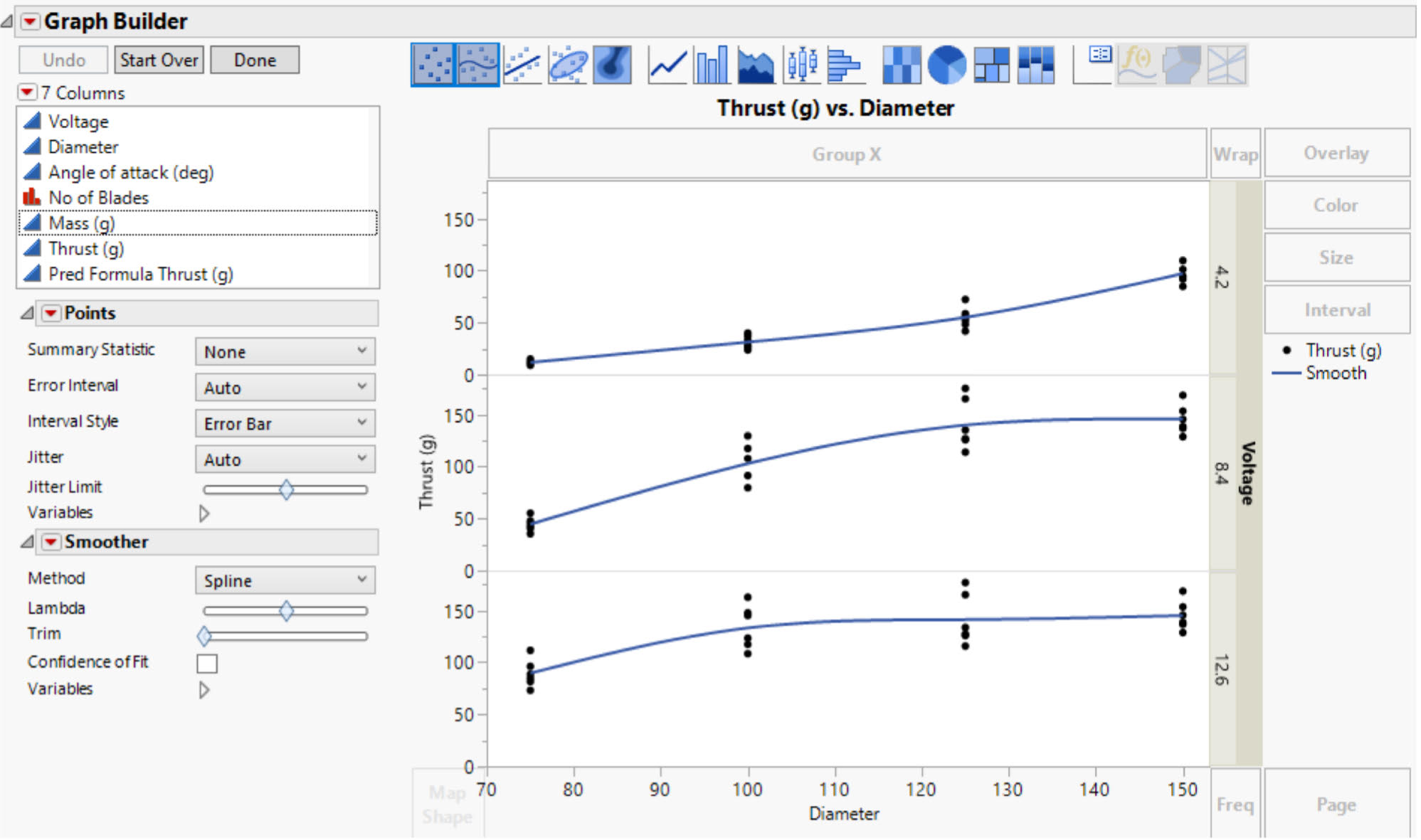

Drone Propeller DOE surrogate model

This project aimed to create a surrogate model that predicts drone propeller performance (thrust per watt) based on a range of design inputs. A Design of Experiments (DOE) approach was used to sample a variety of geometries and operating conditions. The data generated from physical tests was used to fit a hyper-surface which could be used to predict the performance of other propeller geometries.

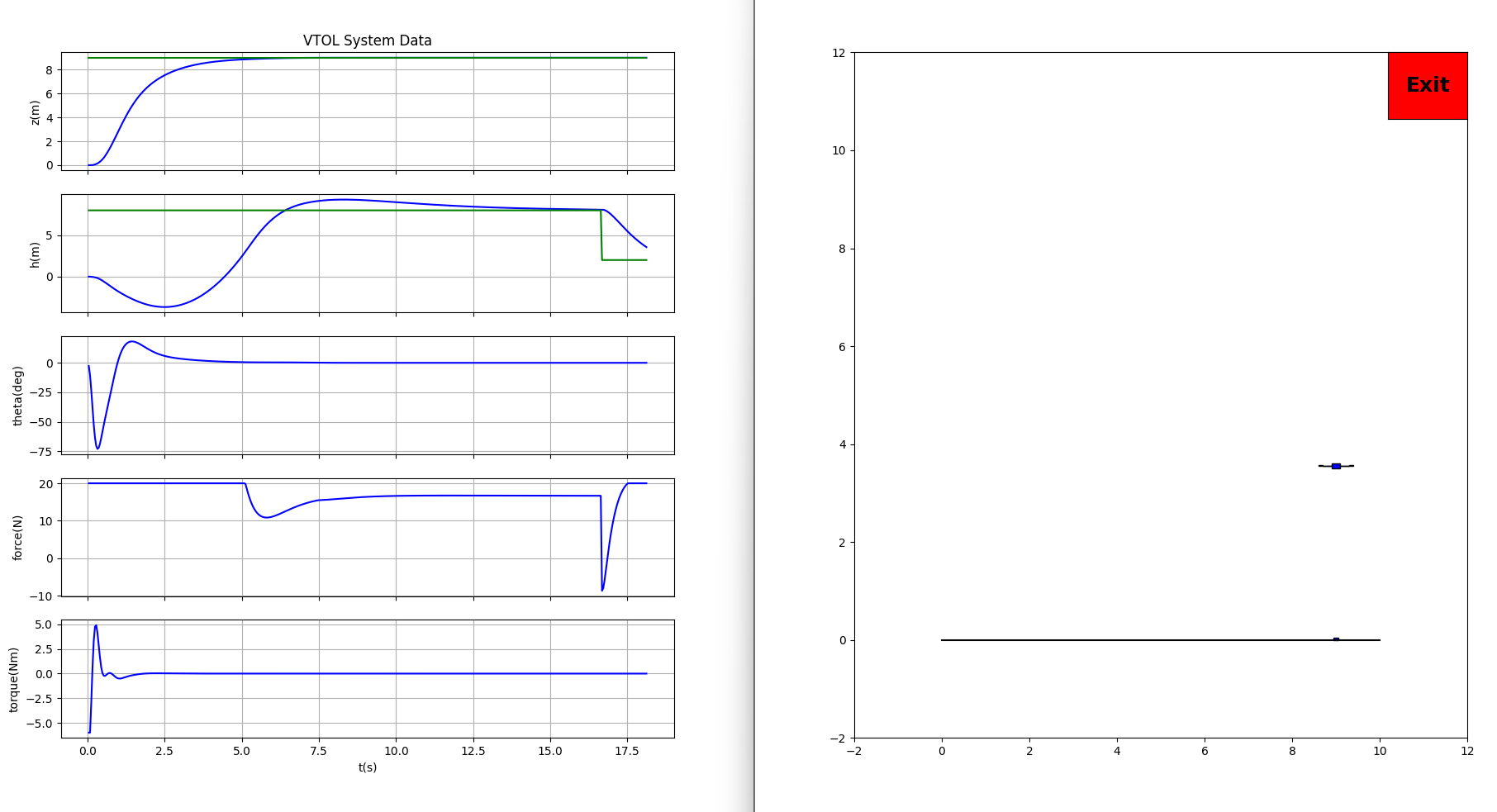

Me En 431 Design of Control Systems

During my senior year, I had the opportunity to take a course on control systems design. The course was comprised of a series of case studies as well as a physical lab. For each of these case studies, I modeled the system behavior using Lagrangian dynamics and implemented control using both PID and state-space controllers, all with tools in Python such as SymPy and NumPy.

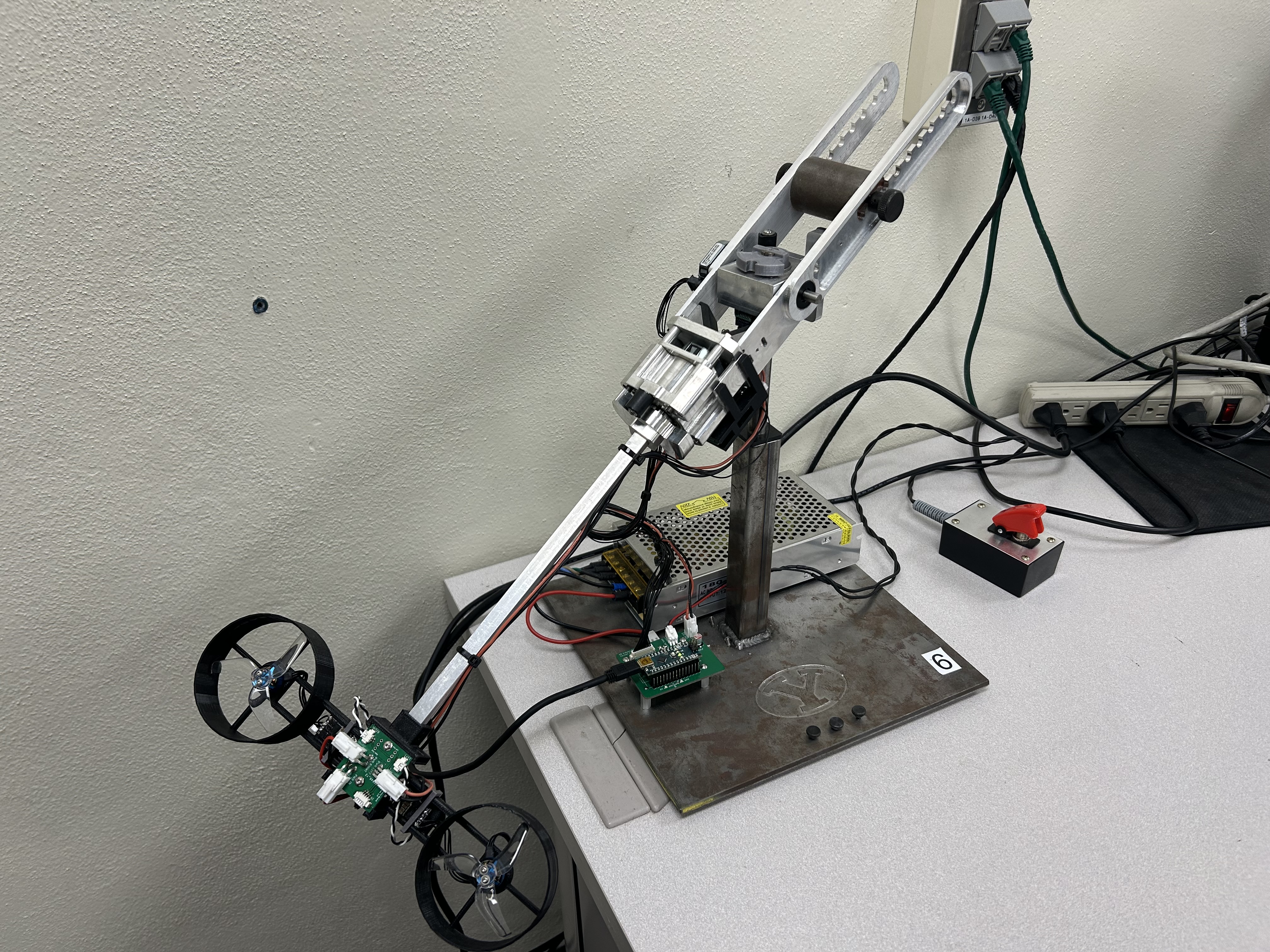

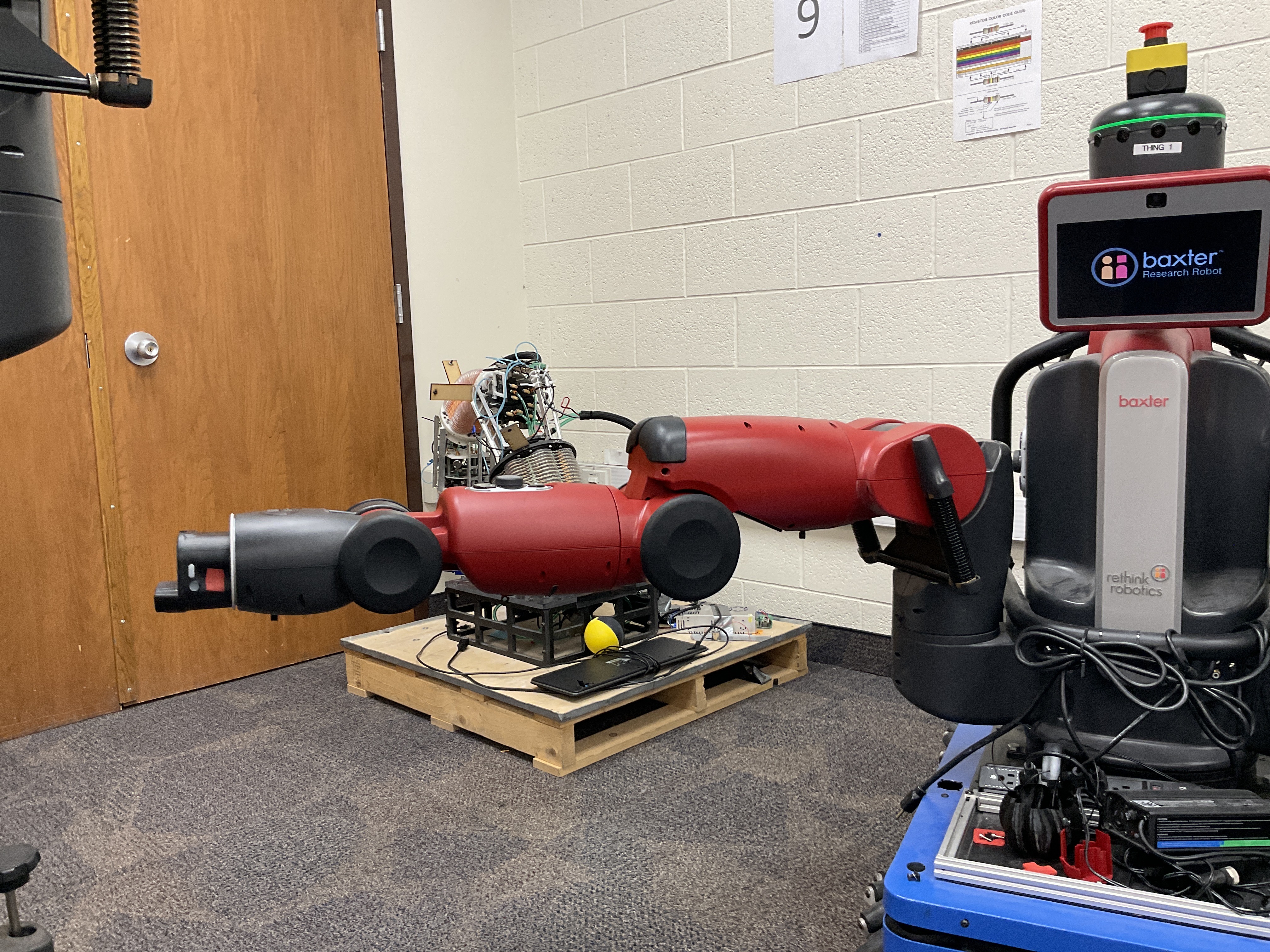

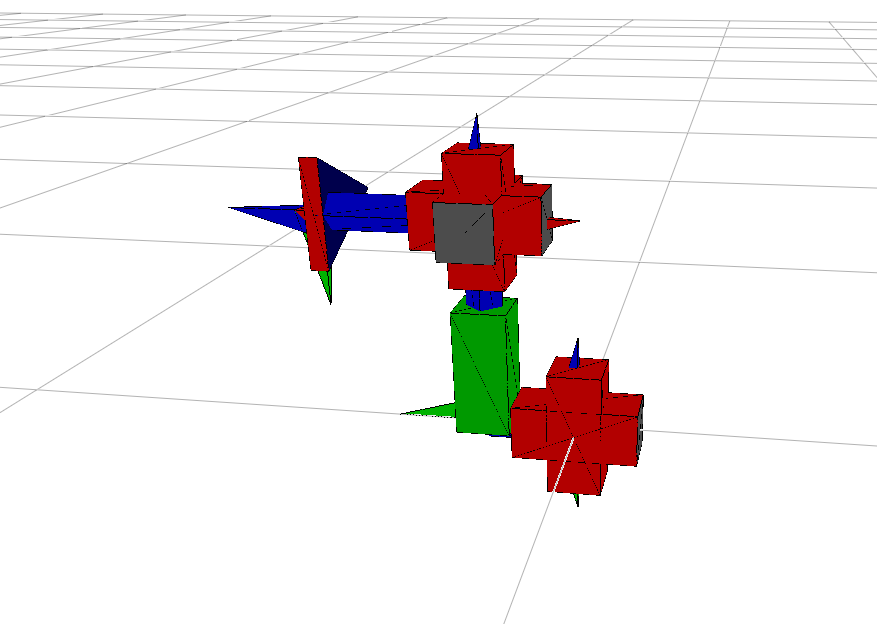

Me En 537 Robotics

In this course, I learned about the fundamentals of robotics, including forward and inverse kinematics, trajectory planning, dynamics, and control. The course was mainly focused on the mathematical modeling of robotic systems, but also had a lab component where I implemented some of the concepts using an industrial robotic arm. The majority of the modeling and mathematics was done using Python libraries like SymPy and NumPy, and we used ROS2 for the lab component.

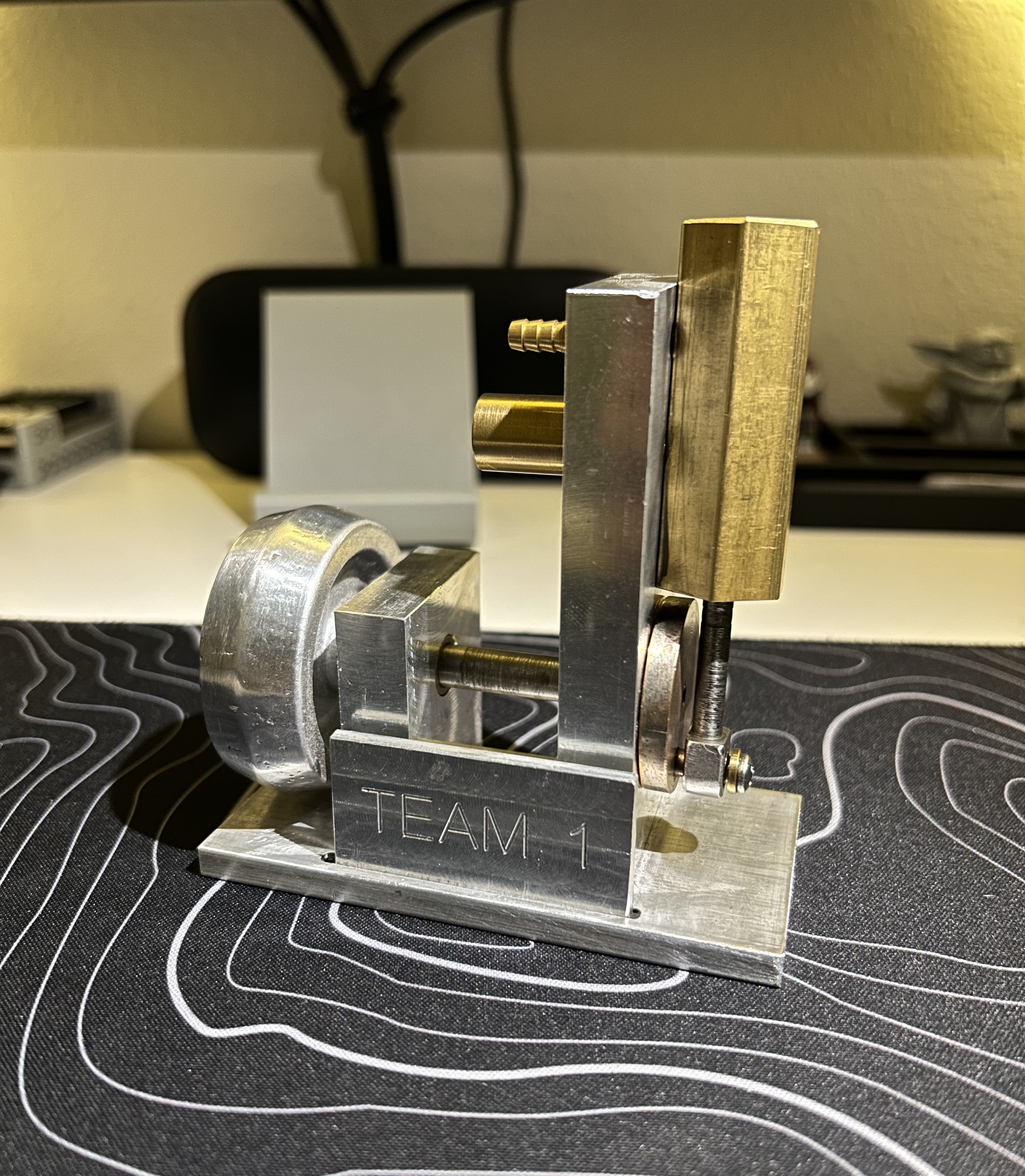

Single Cylinder Air Engine

In a manufacturing processes course, I worked with a team to design and build a single-cylinder air engine. We used a variety of manufacturing methods, including manual milling and turning, metal casting, and powdered metallurgic sintering. We were able to successfully run the air engine at pressures as low as 9 psi.