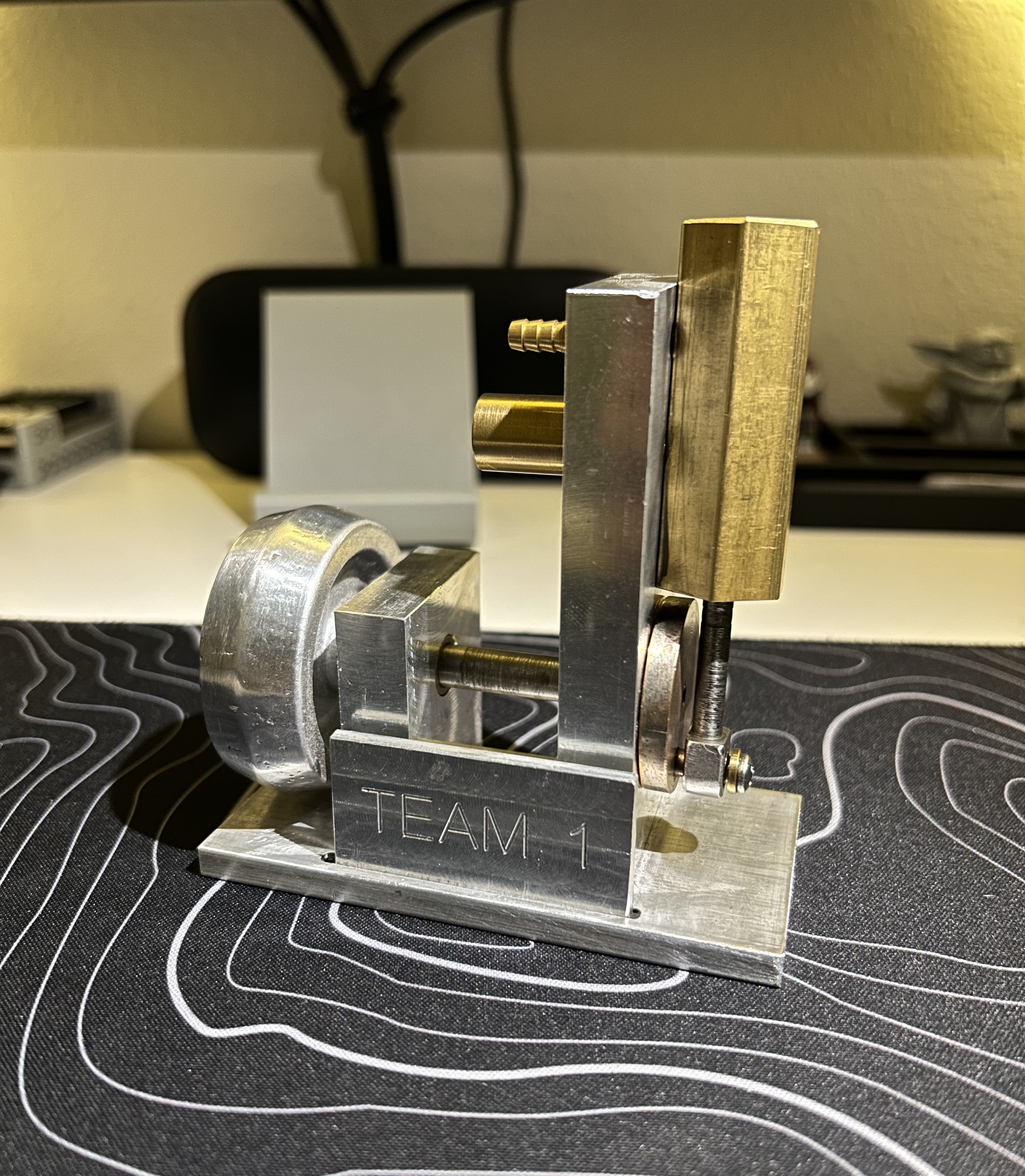

Single Cylinder Air Engine

In a manufacturing processes course, I worked with a team to design and build a single-cylinder air engine. We used a variety of manufacturing methods, including manual milling and turning, metal casting, and powdered metallurgic sintering.

Procedure Applied:

- Designed, toleranced, and determined hole fits for engine components

- Created 3D CAD models of the engine components using Solidworks

- Used manual milling and turning to create the engine components, achieving precise tolerances and surface finishes to ensure proper function and assembly

- Created molds and cast metal parts for the flywheel assembly.

Skills Applied:

- Manual machining (milling, turning)

- Metal casting and mold making

- Powdered metallurgic sintering

- 3D CAD modeling (Solidworks)

Key Outcomes:

- Successfully designed and manufactured a functional single-cylinder air engine capable of maintaining motion at pressures as low as 9 psi.

- Gained hands-on experience with a variety of manufacturing processes and techniques.

Gallery:

Photo of the complete air engine